Concrete pipe seals are specialized components used in the construction and maintenance of concrete pipe systems to provide effective sealing against leaks, infiltration, and other potential issues. These seals are essential for ensuring the integrity and longevity of concrete pipes in various applications, including stormwater management, sewage systems, and culverts. Below, you’ll find a detailed description of concrete pipe seals, including their features, types, installation, and benefits:

Features of Concrete Pipe Seals:

- Material Compatibility: Concrete pipe seals are designed to be compatible with concrete materials, ensuring a secure and long-lasting bond with the pipe.

- Elasticity: These seals are typically made from flexible and resilient materials such as rubber, neoprene, or EPDM (ethylene propylene diene monomer), allowing them to adapt to the shape of the concrete pipe and maintain a watertight seal even in changing conditions.

- Resistant to Environmental Factors: Concrete pipe seals are resistant to a wide range of environmental factors, including water, chemicals, UV radiation, and temperature fluctuations.

- Ease of Installation: They are designed for easy installation, often requiring little more than proper placement and compression to create a watertight seal.

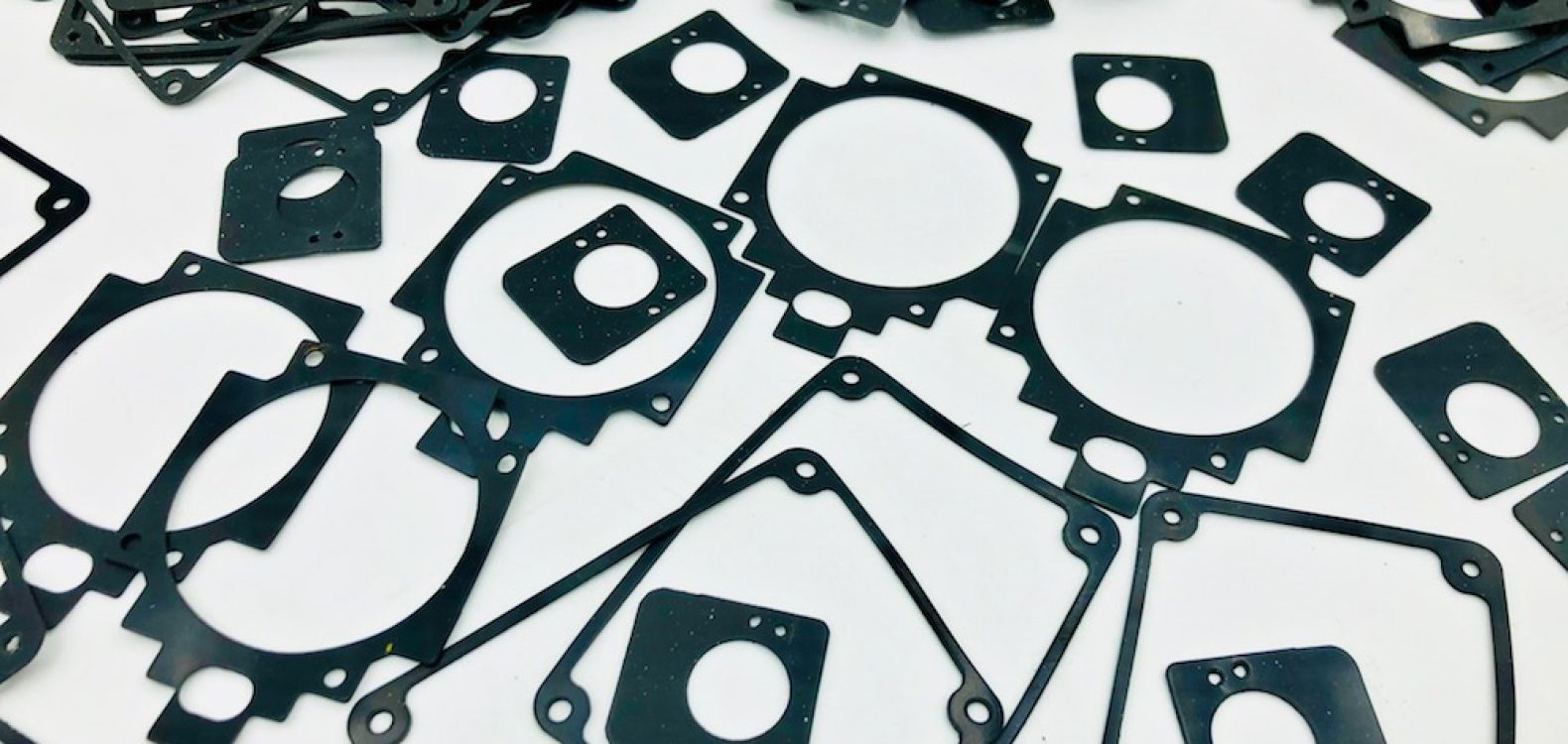

Types of Concrete Pipe Seals:

- Flexible Rubber Gaskets: These gaskets are placed in the joint between concrete pipes to create a tight seal. They come in various shapes, including O-rings and profile gaskets, to suit different pipe designs.

- Mastic Sealants: Mastic sealants are applied to the joints or connections of concrete pipes to fill gaps and create a waterproof seal. They are often used in conjunction with other sealing methods.

- Compression Seals: Compression seals are placed within the joint between concrete pipes and are designed to expand and create a secure, watertight seal as the pipes settle or shift.

- Wraparound Seals: These seals are designed to wrap around the exterior of concrete pipes and are often used to repair damaged pipes or joints.

Installation:

The installation of concrete pipe seals may vary depending on the type and design of the seal, but here are general steps for installing flexible rubber gaskets, a common type:

- Clean the Joint: Ensure that the joint between the concrete pipes is clean, free of debris, and smooth.

- Apply Lubricant: Apply a lubricant to the gasket and the joint surfaces to facilitate proper placement and prevent damage to the gasket during installation.

- Insert the Gasket: Place the gasket into the joint groove, ensuring that it is properly seated and aligned.

- Secure the Pipes: Properly align and secure the concrete pipes, ensuring that they are evenly positioned.

- Compression: As the pipes are pushed together or settled, the gasket will compress, creating a watertight seal.

Benefits:

- Waterproofing: Concrete pipe seals prevent the infiltration of groundwater or the escape of sewage, ensuring the efficient operation of sewer systems and preventing contamination.

- Leak Prevention: These seals reduce the risk of leaks in stormwater management systems, protecting the surrounding environment.

- Longevity: By preventing water and chemicals from entering the pipe joints, concrete pipe seals contribute to the extended lifespan of concrete pipes.

- Easy Maintenance: They simplify maintenance and repair efforts by preventing the need for costly and disruptive pipe replacements.

In conclusion, concrete pipe seals are essential components in the construction and maintenance of concrete pipe systems. They ensure watertight seals, prevent leaks, and contribute to the overall reliability and effectiveness of drainage and sewage systems. The choice of the appropriate type of seal depends on the specific application and requirements of the project.