A dilatation seal, also known as an expansion joint or expansion seal, is a specialized component used in various engineering and construction applications to accommodate the expansion and contraction of materials, structures, or systems due to temperature variations, settling, or other factors. These seals are essential for maintaining the structural integrity, safety, and functionality of various infrastructure elements, such as buildings, bridges, pipelines, and industrial equipment.

Here is a detailed description of dilatation seals:

- Purpose:

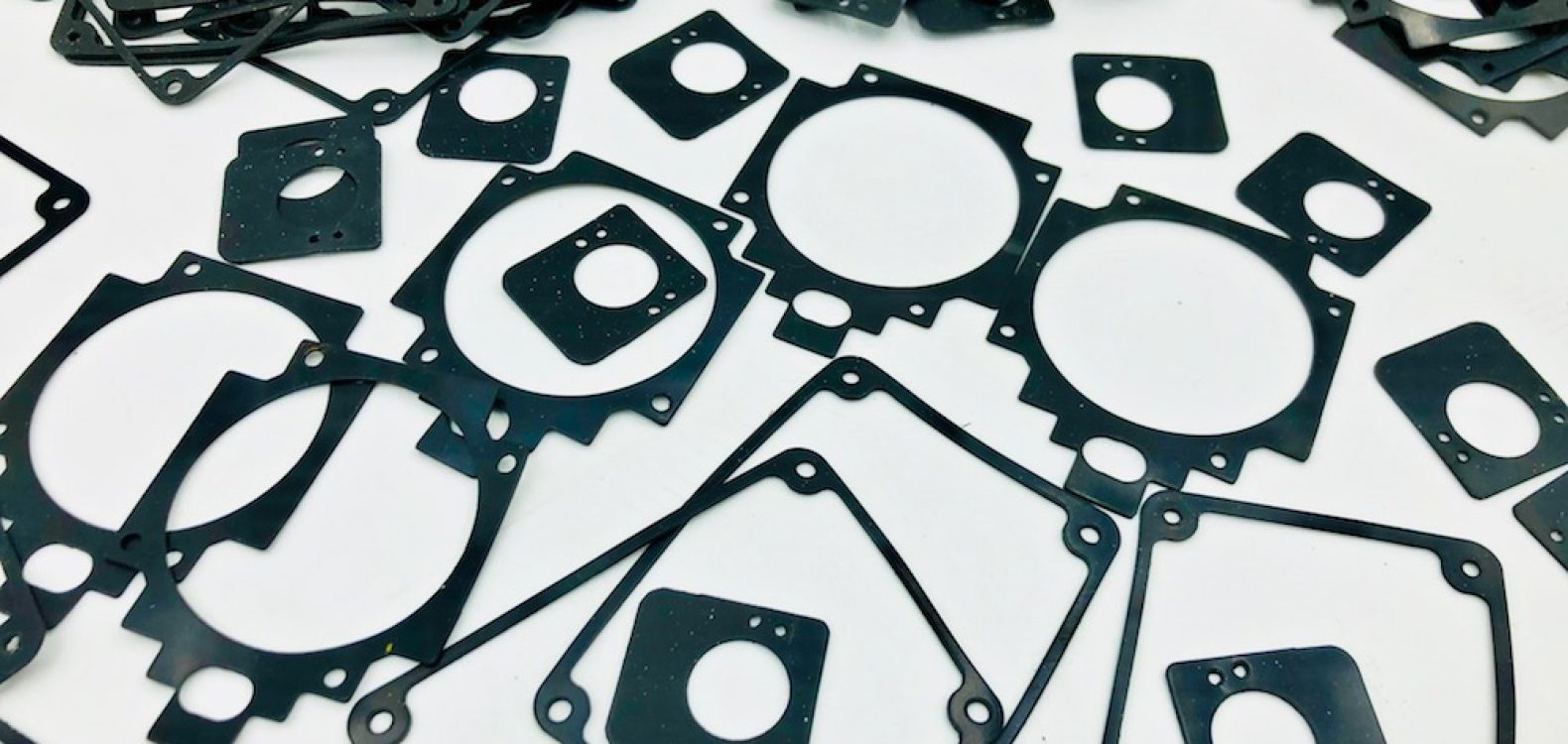

Dilatation seals serve the primary purpose of allowing controlled movement in structures or systems, preventing stress and damage caused by thermal expansion, seismic activity, or settling. They also help in reducing noise and vibration transmission. - Materials:

Dilatation seals are made from various materials, depending on the specific application. Common materials include rubber, elastomers, metal, fabric-reinforced rubber, neoprene, stainless steel, and even combinations of these materials. The choice of material depends on factors such as temperature range, chemical resistance, load-bearing capacity, and durability requirements. - Types:

There are several types of dilatation seals, each designed for specific applications:

- Expansion Joint Seals: These are used in building construction to absorb movement between different parts of a structure, such as between concrete slabs, walls, and facades.

- Bridge Expansion Joints: These seals are employed in bridge construction to allow for movement and maintain the structural integrity of the bridge during temperature changes and traffic loads.

- Pipeline Expansion Joints: Used in pipelines to absorb axial, lateral, and angular movements caused by temperature variations and ground settlement.

- Industrial Expansion Joints: Employed in industrial equipment and machinery to isolate vibration, absorb thermal expansion, and reduce noise.

- Installation:

The installation of dilatation seals requires careful consideration of the application and the type of seal used. Typically, these seals are installed in gaps or spaces where movement is expected. Proper anchoring and fastening methods are crucial to ensure that the seal functions effectively. - Maintenance:

Dilatation seals require regular inspection and maintenance to ensure their continued functionality. Maintenance may involve cleaning, lubrication, and periodic replacement of worn or damaged components. Neglecting maintenance can lead to seal failure and potential structural or system damage. - Design Considerations:

Engineers and designers must consider factors such as temperature variations, expected movement, load-bearing capacity, and chemical exposure when selecting and designing dilatation seals for a particular application. Proper design is crucial to prevent seal failure and maintain structural integrity. - Benefits:

The use of dilatation seals offers several benefits, including:

- Preventing structural damage and failure.

- Extending the lifespan of infrastructure elements.

- Reducing maintenance and repair costs.

- Enhancing safety by minimizing the risk of accidents or collapses.

- Minimizing noise and vibration transfer in buildings and machinery.

In summary, dilatation seals are essential components in various engineering and construction applications, providing a means to accommodate movement and prevent structural damage and failure due to temperature variations, settling, or other factors. Proper selection, installation, and maintenance of these seals are critical for the safety and longevity of structures and systems.