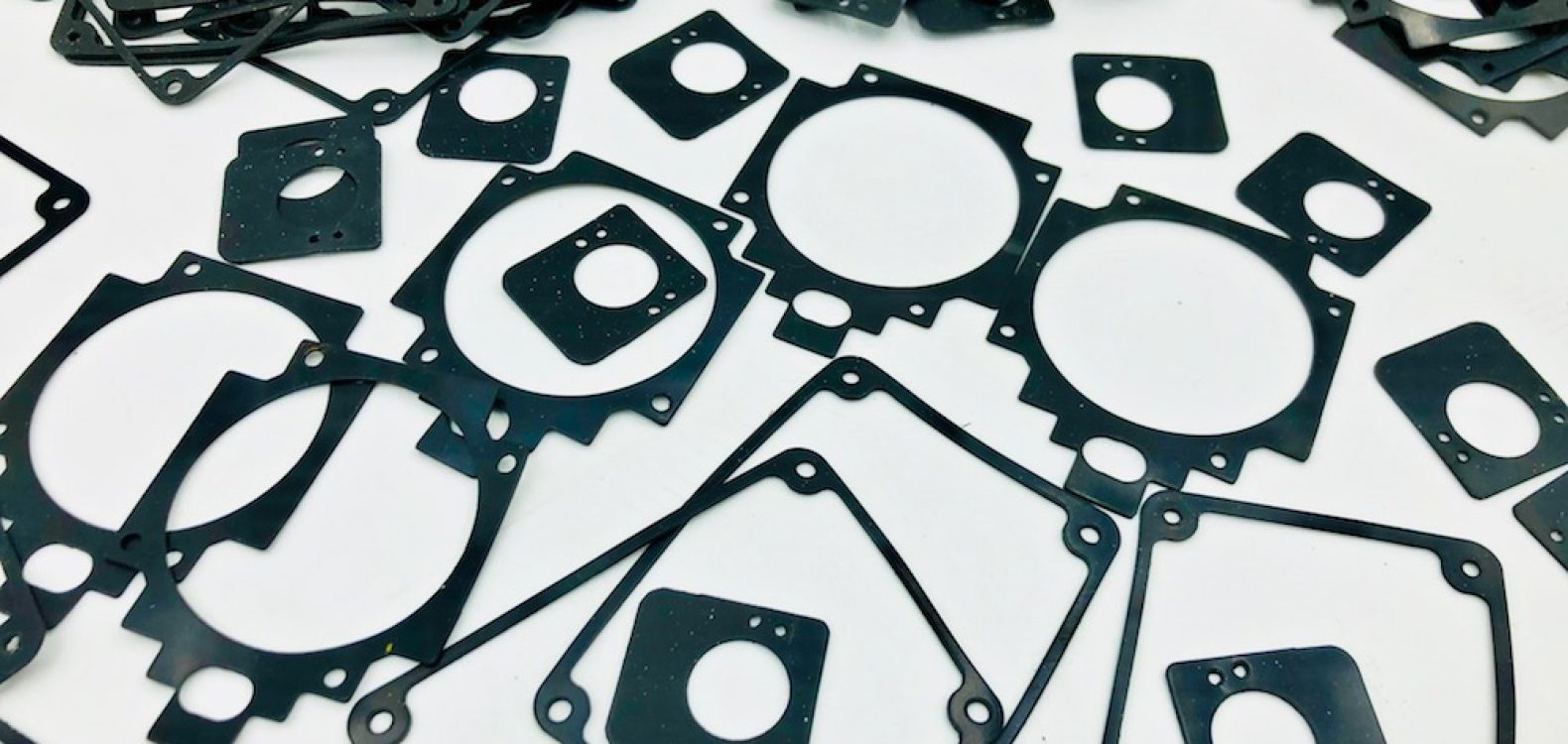

EPDM (Ethylene Propylene Diene Monomer) rubber seals are widely used in various industries and applications to provide effective sealing solutions. These seals are made from EPDM rubber material, which possesses excellent properties such as resistance to weathering, UV radiation, ozone, temperature extremes, and a wide range of chemicals. EPDM rubber seals are known for their durability and versatility in creating airtight and watertight seals. Below, you’ll find a comprehensive description of EPDM rubber seals, including their features, applications, benefits, and considerations:

Features of EPDM Rubber Seals:

- Weather Resistance: EPDM rubber seals excel in outdoor applications due to their exceptional resistance to weathering, UV radiation, and ozone exposure.

- Temperature Stability: These seals maintain their sealing properties across a wide range of temperatures, from extremely hot to cold conditions, without becoming brittle or losing elasticity.

- Chemical Resistance: EPDM rubber exhibits good resistance to a variety of chemicals, including acids, alkalis, and oxidizing agents, ensuring its longevity in diverse environments.

- Flexibility and Elasticity: EPDM rubber is inherently flexible and elastic, allowing it to conform to irregular surfaces and maintain a reliable seal even under compression.

- Low Compression Set: EPDM rubber seals have a low compression set, which means they can retain their original shape and sealing effectiveness even after prolonged compression.

- Electrical Insulation: EPDM rubber is an excellent electrical insulator, making it suitable for sealing electrical enclosures and components.

Applications of EPDM Rubber Seals:

EPDM rubber seals find wide-ranging applications across various industries, including:

- Automotive: EPDM seals are commonly used in vehicles for sealing doors, windows, hoods, trunks, and various engine components, providing weatherproofing, sound insulation, and vibration dampening.

- Construction: These seals are used in the construction industry for sealing windows, doors, roofing systems, and HVAC (Heating, Ventilation, and Air Conditioning) equipment in residential, commercial, and industrial buildings.

- Electronics: EPDM rubber seals protect electrical enclosures, control panels, and outdoor electronic equipment from moisture and environmental elements.

- Industrial Machinery: EPDM seals serve as gaskets and seals in pumps, valves, compressors, and other industrial equipment, ensuring leak-free operation.

- Marine: They are essential in marine applications for sealing hatches, ports, and other openings to prevent water ingress, maintaining vessel integrity.

- HVAC: EPDM rubber seals are used in HVAC systems for sealing ducts, pipes, access panels, and other components, contributing to energy efficiency by preventing air leaks.

- Water and Wastewater: These seals are used in water distribution and wastewater systems for sealing pipes, fittings, connectors, and manholes to prevent leaks and contamination.

Benefits of EPDM Rubber Seals:

- Longevity: EPDM rubber seals have a long service life due to their resilience and resistance to environmental factors, making them a cost-effective sealing solution.

- Energy Efficiency: They help improve energy efficiency by sealing gaps and preventing drafts, reducing heating and cooling costs.

- Chemical Resistance: EPDM rubber seals are suitable for applications exposed to various chemicals and liquids.

- Versatility: They can be used in both indoor and outdoor applications across different industries.

- Low Maintenance: EPDM rubber seals typically require minimal maintenance and are easy to replace when necessary.

Considerations:

- Chemical Compatibility: Ensure that EPDM rubber is compatible with the specific chemicals and fluids in your application.

- Temperature Range: While EPDM has a broad temperature range, extreme temperatures might require specialized materials.

- Compression Set: Over-compression or excessive stress can lead to a loss of sealing effectiveness.

In summary, EPDM rubber seals are versatile sealing components known for their exceptional weather resistance, temperature stability, and chemical resistance. They play a vital role in preventing leaks, ensuring energy efficiency, and protecting against environmental factors in a wide range of applications and industries. Proper selection and maintenance of EPDM rubber seals are essential for achieving effective and long-lasting sealing solutions.